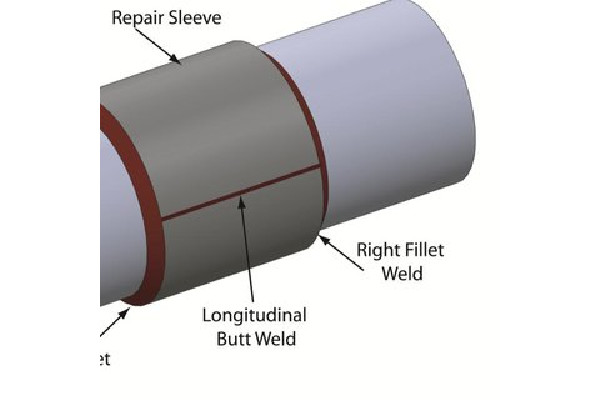

When it is not possible to repair/replace the pipelines throgh Line Stop method, We offer the Pipe Repair Sleeves. These are placed on the pipelines in two halves and welded to become a permanent part of the pipe covering the damaged section of it. This operation also requires high precission and special care as we are operating on the weakest section of the pipeline.

We adopt the same procedure used for In Service Welding, with extra preacutions and safety measure. Our Team of experts conduct a detailed survey on the pipeline to check its feasibility for this operation, which includes Thickness test, Positive Material Identification, Finite Element Analysis, Ultrasonic Lamination (Rolling Defect) Test etc.

Pipe repair sleeves can be used to regain the integrity of pipelines lost due internal corrossion, External Damages such as dents, drags and sufrace deffects such as cracks.

We manufacture and weld repair sleeves starting from 6” to 48” of different thickness and material to suit the mainline.